Advice, Buying Guides, Glossary

Folding Knife Lock Types

There are so many types of folding knife locking mechanisms, it can be a little daunting at times.

Different manufacturers also have their own variations on each locking type, which they rename for their own marketing purposes, and this can further add to the confusion.

Read on for our handy guide to the different knife locking mechanisms available.

Frame Lock Folding Knives

Frame locks are one of the most popular locking mechanisms available, especially on higher end knives. The major advantages of a frame lock knife are its simplicity and strength.

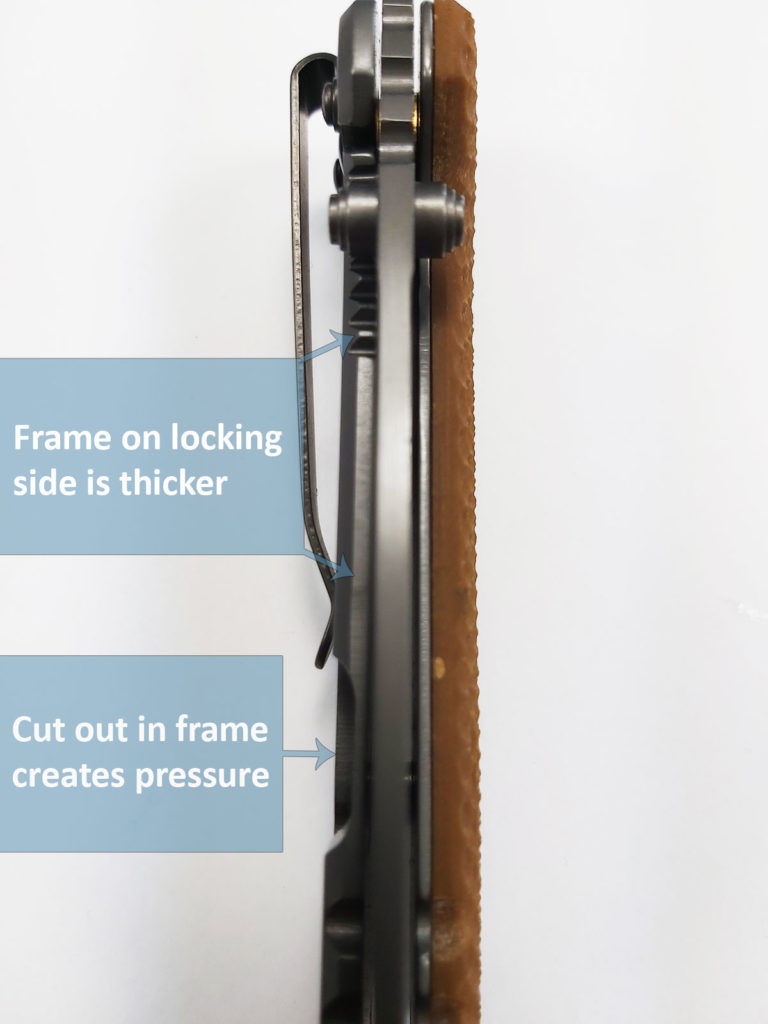

The mechanism works by utilising the frame of the knife itself to lock the blade. The frame, on the locking side, is thicker and forms the handle on one side.

There is a cutout along the spine of the knife which creates pressure and causes the frame to push inward.

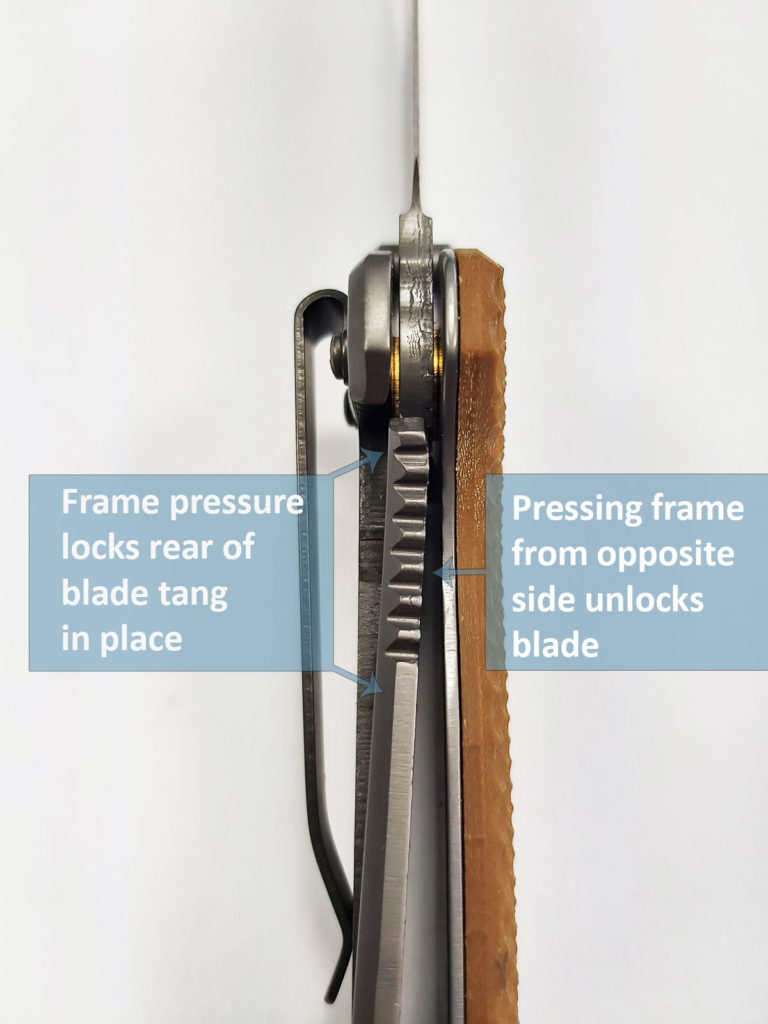

When the blade is unfolded, this pressure forces the frame inward enough to lock the blade firmly in place by engaging the rear of the blade tang.

When the blade is fully unfolded, the blade itself cannot move as the frame now engages the rear of the blade tang.

To unlock the blade, applying pressure on the frame in the opposite direction frees the blade to move again.

In most frame lock knives, there is a detent ball which engages with a corresponding hole in the base of the blade to keep it closed.

It also provides some tension for the ‘snappy’ opening. Above the pivot there is a stop pin which engages the blade in its fully open position, further helping to eliminate wear and tear on the locking mechanism.

Whilst this is a very simple system for a locking mechanism, it is extremely robust and has a lot of strength to keep the blade open.

Strengths – Sturdy construction, very strong and has fewer parts so there is less likelihood of failure.

Weaknesses – Action is dependant on good pivot tension. This mechanism relies on one side of the frame being used so is not ambidextrous.

The knife featured above is a Coast FX350 Frame Lock Folder in Tan.

Slipjoint Folding Knives

Slipjoints are the type of mechanism most people will be familiar with, If you’ve used a swiss army knife or similar, chance are it utilised a slip lock. It does provide some safety for the user without using a locking mechanism.

In basic terms a slipjoint knife utilises a spring which sits along the spine of the knife which is anchored to the handle halfway down.

This spring presses against the bottom of the blade tang, putting pressure on the blade and keeping it closed.

When you pull the knife open, the spring snaps down on a rectangular cut out in the top of blade tang, locking the blade in place without a lock.

In order to close the blade, the spring needs to be overcome, preventing the blade from moving freely and simply flopping open and shut.

It gives the feeling of tension when opening and closing with a ‘snappy’ feel when the blade is engaged.

Sometimes there may be a flat area which has been ground onto the tang midway between the open and closed position. This creates a half stop whilst opening, adding an extra layer of safety.

Not all slipjoint knives have a half stop.

Strengths – Simple and reliable, easier to manufacture, definite ‘snap’ when opening and closing, legal in most regions due to lack of an actual lock.

Weaknesses – Slipjoint knives DO NOT lock. Both hands are needed to open.

The knife featured above is a Lansky World Legal Knife.

Lockback Folding Knives

The Lockback knife is a simple mechanism which derives from the slipjoint method. They are sometimes known as back locks, mid locks or spine locks.

In a similar way to a slipjoint, the knife features a locking blade which runs down the spine of the knife.

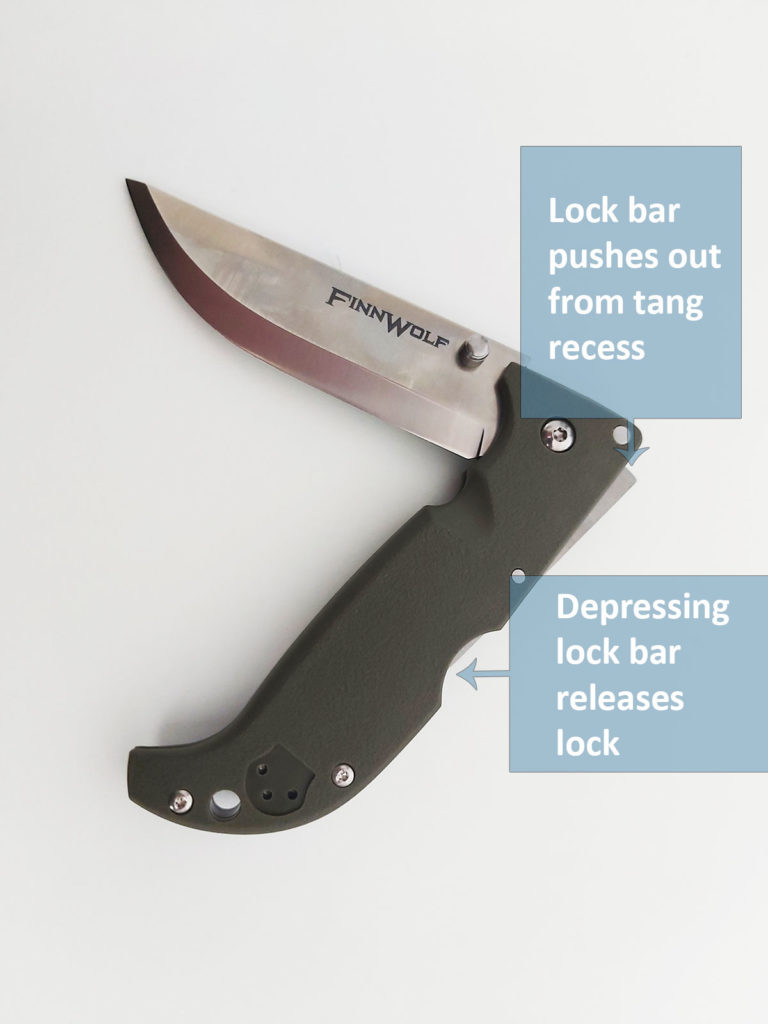

The lock bar is pinned in place with a pivot in the middle. There is a spring anchored further toward the end of the handle, putting upward pressure behind the pivot point.

This pushes the front of the lock bar down.

In a similar manner to slipjoint knives, when the blade is opened it forces the user to overcome the spring tension, preventing the blade from flopping open.

Once fully open the front section of the lock bar nestles in a cut out in the blade tang, locking the blade in place.

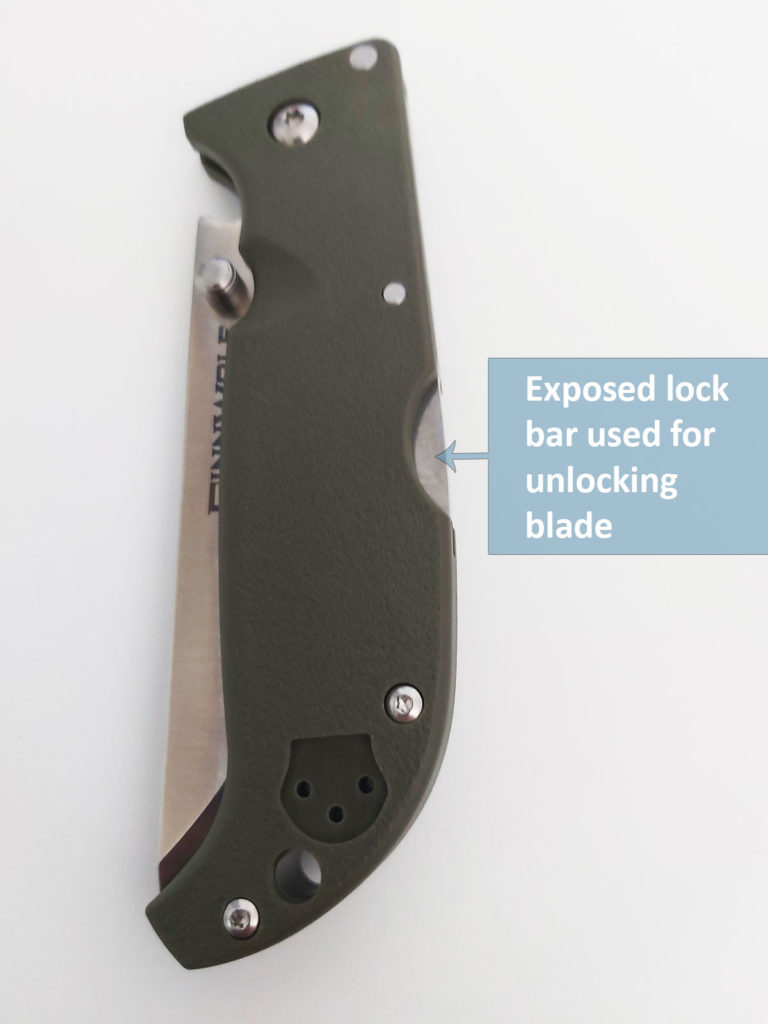

The difference to the slipjoint is that in order to close the knife the lock bar must be depressed. Along the handle of the knife there is a cutout area, exposing the lock bar.

Depressing the lock bar in this area puts pressure on the spring and releases the lock bar from the blade tang recess and the blade can be closed.

Without depressing this area of the lock bar, the blade will not close.

There are differences in Lockback design used by different manufacturers. There may be, for example, a stop pin included so that the blade locking is not entirely reliant on the lock bar, helping to prevent wear and tear to the lock bar.

Generally, they all rely on the same principle of a lock bar as the main mechanism.

As the locking mechanism on a lock back knife is located along the spine, it is easy to use in both hands as opposed to some locking mechanisms located on one side of the knife so would not be suitable for use by everyone.

Strengths – Completely ambidextrous, generally very strong as the locking mechanism is normally as thick as the blade stock.

Weaknesses – Can suffer wear and tear after repeated opening. Care required when using one handed as a finger may be in the way of the blade.

The knife featured above is a Cold Steel Finn Wolf.

Button Lock Folding Knives

Knives with a button lock utilise a sprung tension button near the pivot of the blade and handle. When the blade is fully open or fully closed the sprung button pin locks into a recess on the blade tang.

They were historically used on ‘automatic’ blades which utilise a sprung blade so that when the button is depressed, its springs open automatically.

Pushing the button depresses the button pin, unlocking it from the recess in the tang. This means that the blade is locked when fully open and fully closed.

As the button is positioned on one side, they are not ambidextrous, so not suitable for all users.

Strengths – Very strong lock, hand is not exposed when opening closing.

Weaknesses – Can be expensive to manufacture due to increased complexity, not ambidextrous.

The knife featured above is a Schrade Push Button Lock Folding Knife with Drop Point Blade.

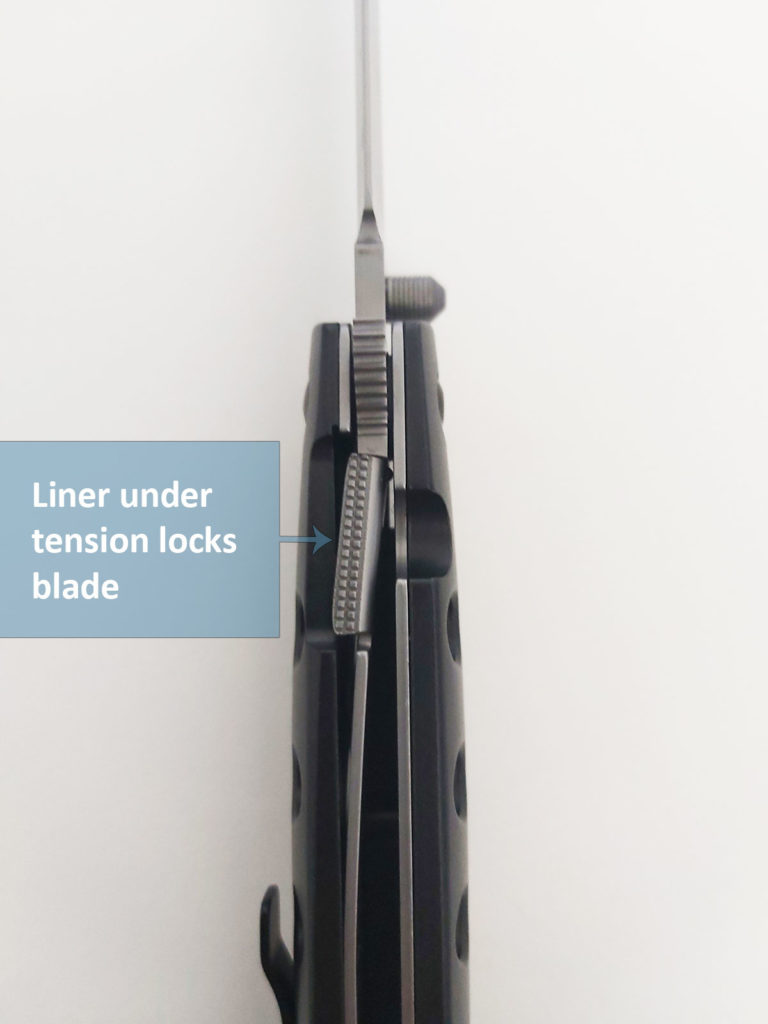

Liner Lock Folding Knives

Liner locks are an incredibly popular and cost-effective style of locking mechanism.

Whilst they may not be the most exciting or creative method for locking a blade, they are both easy to use and practical.

The liner lock design utilises one of the blades liners, with a cut out and slight bend to create a spring effect.

They are similar in mechanism to the frame lock mechanism, in that the liner is sprung and engages the blade tang when open.

There are a few variations on this type of locking mechanism which utilise a stop pin and detent ball to hold the blade closed.

Strengths – Simple and reliable, easier to manufacture, familiar to most people.

Weaknesses – Thinner liner lock means not suitable for heavy use, not ambidextrous, fingers in path of blade so care is required.

The knife featured above is a 4″ Cold Steel Ti-Lite Aluminum.

Axis Lock Folding Knives

The axis locking mechanism is deceptively simple. There is a slot cut in the handles and liners near the pivot. Inside this slot rides a bar which acts as the ‘button’. This slides under tension to unlock the blade.

Springs at either side of this bar apply equal pressure, so when the blade opens the spring forces the bar into a tang recess and locks the blade. Often a stop pin is also used to aid stability.

There are multiple variations on this design featuring bearing-based pivots and different shapes of mechanism but functionally they are pretty much the same mechanism.

Strengths – Ambidextrous, hands kept away from blade, easy to open, strong and stable locking.

Weaknesses – springs more prone to break, more moving parts so more expensive to manufacture, prone to collect dirt on moving parts.

The knife featured above is a Willumsen RED E.

Folding Knife Variants

There are a myriad of variations on the basic mechanisms. here are a few notable locking mechanisms from leading knife manufacturers.

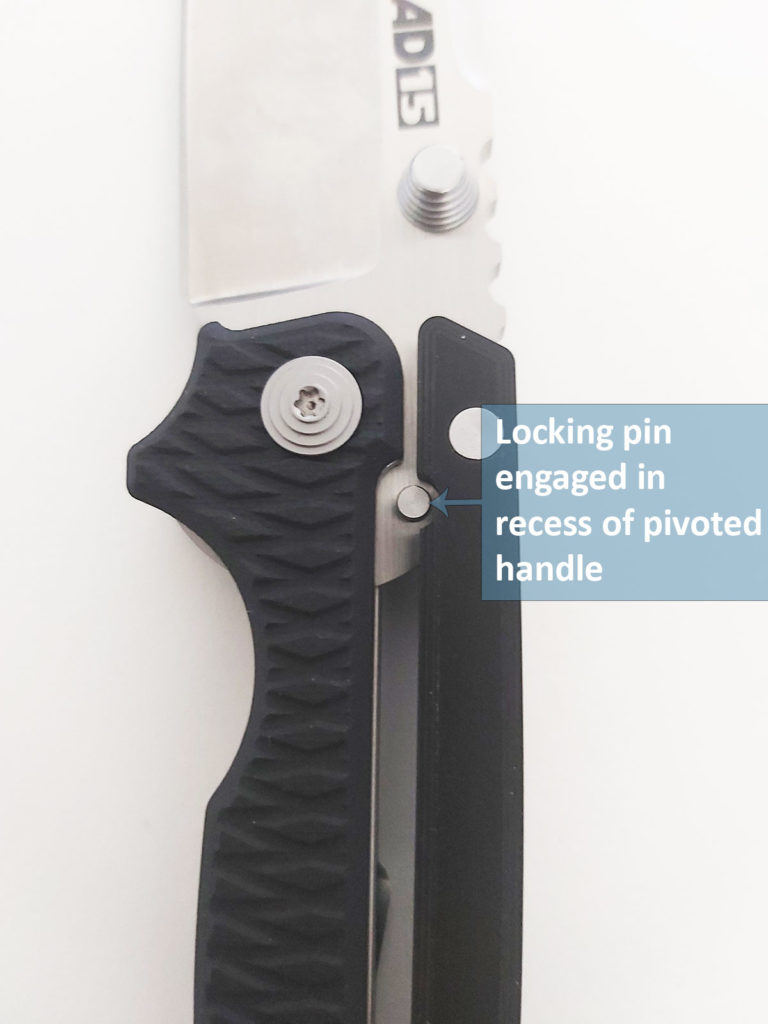

Cold Steel manufacture a knife (AD-15) which features a patented hybrid locking mechanism called the ‘Scorpion lock’.

The locking mechanism has a handle which has a pivoted section kept under under tension.

This section pushes in and out at one end whilst pivoting at the opposite end. This allows the blade to open and close smoothly whilst providing a solid locking mechanism.

When fully open a locking pin fits into a cut out on the pivoted section. It’s a truly unique design and very comfortable to use.

The knife featured above is a Cold Steel AD-15.

Hopefully this guide will prove to be useful when you are considering exactly what kind of folding knife you are looking for.

With such a wide variety of folding knife options out there, you’re sure to find the right knife locking mechanism which suits your needs.

Take a look at our massive selection of folding knives from leading knife makers – all at the best prices online.